The Quickest Way To Improve Distribution Uniformity

July 31, 2014

Are dry spots showing up in your customer's turf? The irrigation system may have a problem with its uniformity.

In Part 7 of our Drought Solutions video series, you'll learn about distribution uniformity (DU) and the coefficient of uniformity (CU) and how to increase the system's uniformity by matching precipitation rates.

Improving Distribution Uniformity - Video Transcript

No matter how smart our system is, if our sprinkler heads aren't installed properly, it doesn't matter.

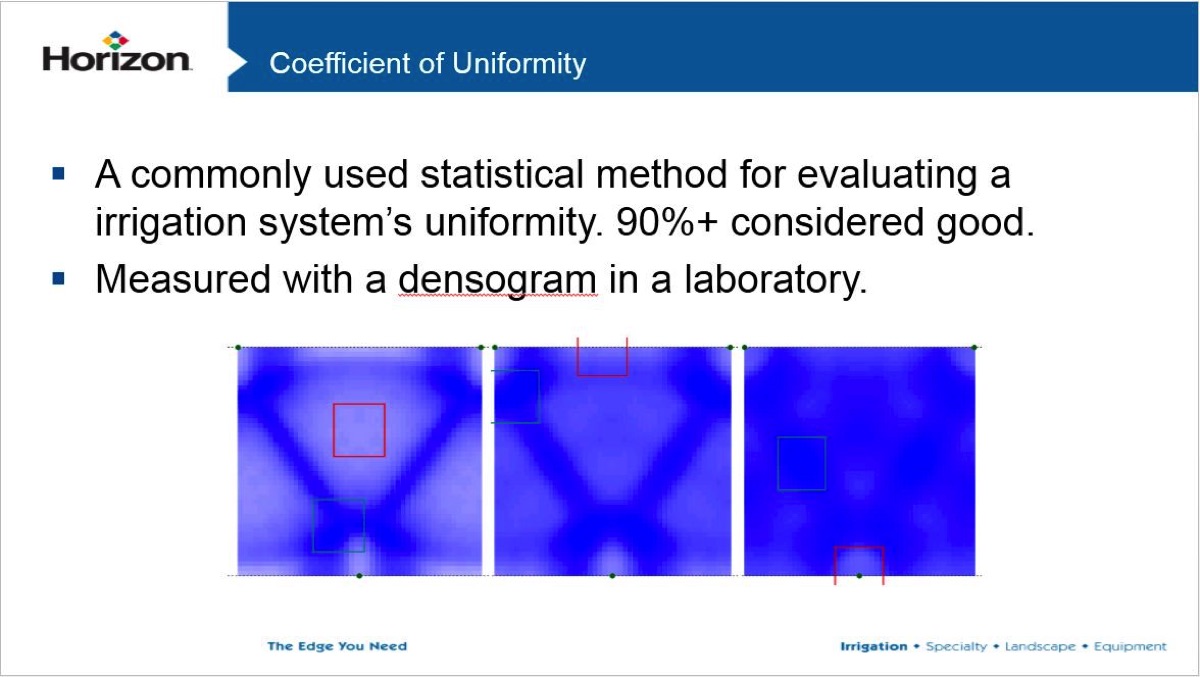

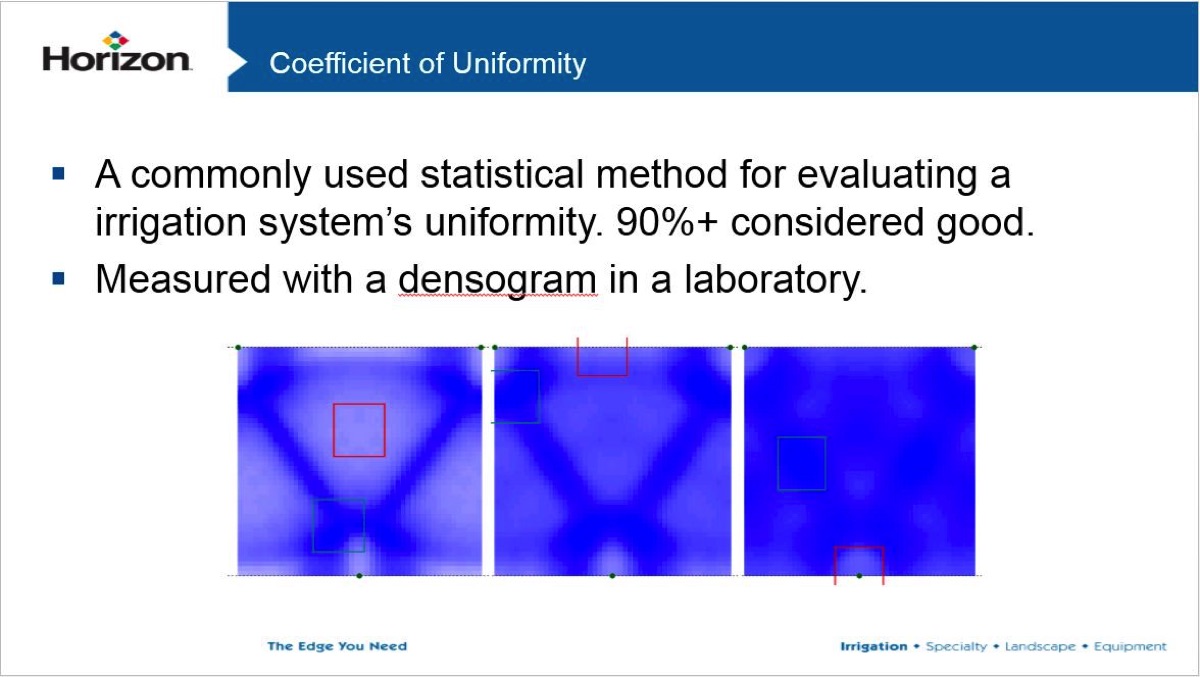

Coefficient of uniformity (CU) is a statistical method of evaluating a system's uniformity. That's how the system is working as a whole.

The CU is all measured on a densogram and it's in a laboratory situation. Every manufacturer's catalog has their laboratory numbers in there. These manufacturers spend millions of dollars on these laboratories where they do the testing of these heads.

They want their numbers to be better than their competitor's numbers. They're spending tons of money. The one thing they're shy on is running this whole thing in a vacuum.

They're in buildings. Absolutely zero humidity. Absolutely zero airflow. They've got these things pinned down to where this is what my sprinkler head does.

So when you're designing or you're reading the charts, just remember that all of those charts are done in a laboratory. These numbers are done in a laboratory. They can tell us some information, but let's make sure that we're not relying on that 1000%. And we'll talk about that a little bit more on spacing.

Dry Spots & Stretched Systems

So your distribution uniformity (DU), that's the spacing. This system is a gear drive rotor system. It's set up on triangle spacing and true to fashion, you've got some dry spots here. You got spots here, dry spots here, you got a big old dry spot here.

Traditionally we call this a stretched system. Why is it stretched? It's because this sprinkler head is not watering that one over there and that sprinkler head's not watering this one over here. They have to water each other.

Spray system, gear drive rotor system. To get the water to go that far, it has to water itself. I mean it can't water itself. It has to rely on its neighbor to water it. if you don't have at least head to head coverage in those situations, you're gonna get dry spots.

And these dry spots may not show up right now. Man, my system works great 99% of the winter. Summertime come along, my customers aren't very happy. We got doughnuts. Big doughnuts around gear drive rotors. Big doughnuts around spray heads.

The Wrong Way to Fix a Dry Spot

What's the common way to cure a doughnut? How do you fix a doughnut? Out in the field, what's the number one fix? The first thing guys do?

Up the run time. Oop we need more water. Well there goes your 20% savings cause now you're micro flood irrigating instead of having your system set up properly. Let alone the 50%, 60%, 70% more water that you're gonna use by doing stuff like that.

So what these things show us in a laboratory is how the system works in a stretch situation. If you look now, we get over here, the system is getting a little better.

Improving Uniformity with Matched Precipitation Rates

It may be because they're nozzling properly. Ok, beautiful, matched precipitation rate. Pretty cool word. It's even better with gear drive rotors because they give you a whole rack. 1 head, 12 nozzles. That's cool! 12 nozzles. I wonder why I need 12 of them for 1 head?

What happens? Every single head out there has got a #7 nozzle in it. So this little corner and this little corner has got a #7. And this little corner's got a #7.

So if we've got a #7 nozzle here, that's a quarter spray. A #7 nozzle there, that's a half spray. And a #7 there, that's a full spray. What's the problem with that?

That full spray is gonna be a dry spot. That's gonna be a doughnut. You're watering 4 times as much area as this quarter. That's why they give you a rack of 10 nozzles. That's why they give you that book that says, OK if that full circle, if we put up for 4 gallon/minute nozzle in there, that half has to be a 2 gallon/minute nozzle and this quarter has got to be a 1 gallon/ minute nozzle.

They all say they're matched precip rate, but you gotta change the nozzles. They can't all be a #7 nozzle. Let alone a #10 nozzle. A #10 nozzle puts out about 10 gallons/minute.

I can walk onto your sites today and I will start pulling up rotors and they all have the same nozzle in them. I see architects design them with all the same nozzle. Any architects? Design them with all the same nozzle in it. It's like guys, what did you do that for?

With all the same nozzle in them, you're going to get some crazy looking stuff. When you start getting closer to match precip, you're going to get it right.

Match precip rate. Now, on our match precip rate sprays heads, you don't have to do that. They automatically do it. The manufacturer says it's a fixed arc. Here's what it's gonna do. At this arc, here's our precip.

So MPR - Matched Precip Rates - when they did it in spray heads, it's fine. But in gear drive rotors, it's up to you. It's up to us as water managers.

That's the low hanging fruit that we can grab onto and say, you know I know what's wrong with your system. I mean this quarter over here, I'm up to my ankle in mud and we got a doughnut around that full circle on exactly the same valve. That's the opportunity.