Sprinkler Spacing 101: How To Avoid Dry Spots And Boost Uniformity

August 5, 2014

When dry spots appear around sprinkler heads in summer, there is often a spacing problem that needs to be corrected.

In Part 8 of our Drought Solutions video series, you’ll discover why you shouldn’t completely trust the manufacturer’s specifications and learn a few approaches that can help you properly space heads.

Optimize Your Sprinkler Head Spacing - Video Transcript

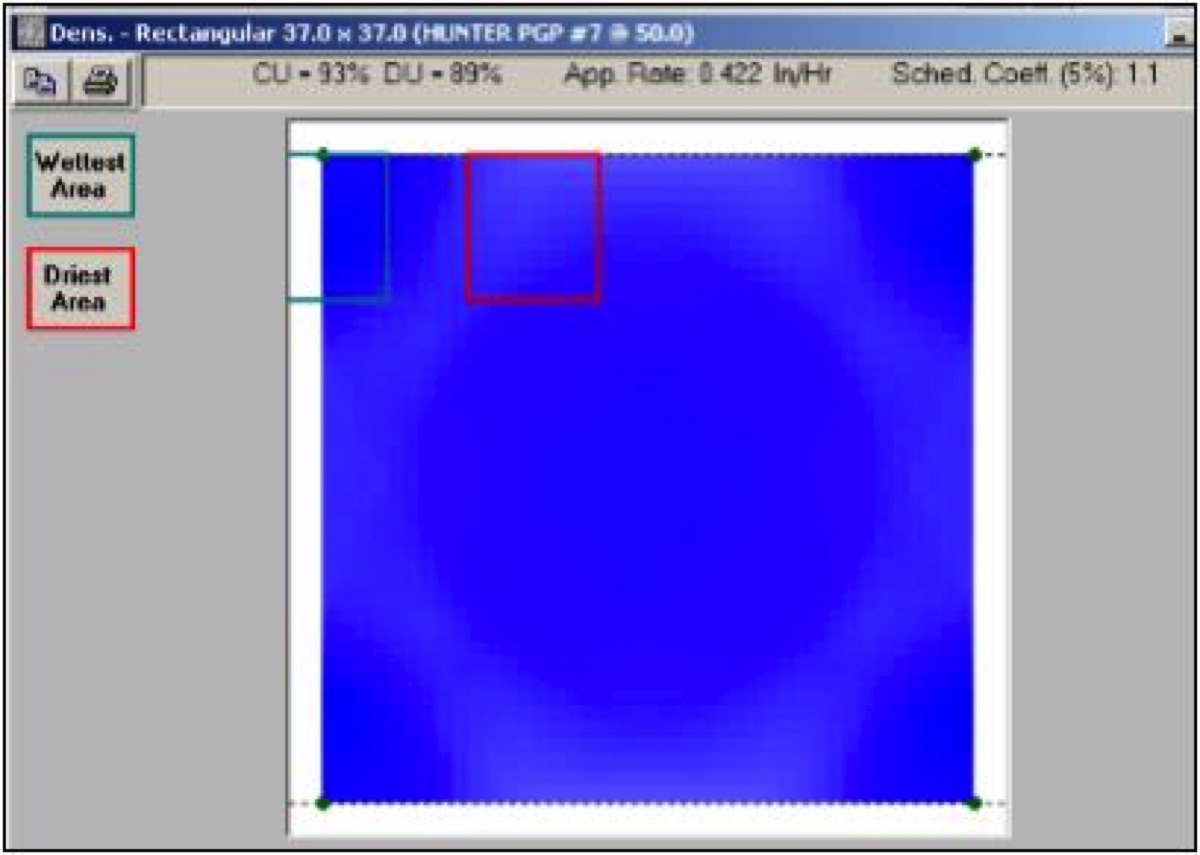

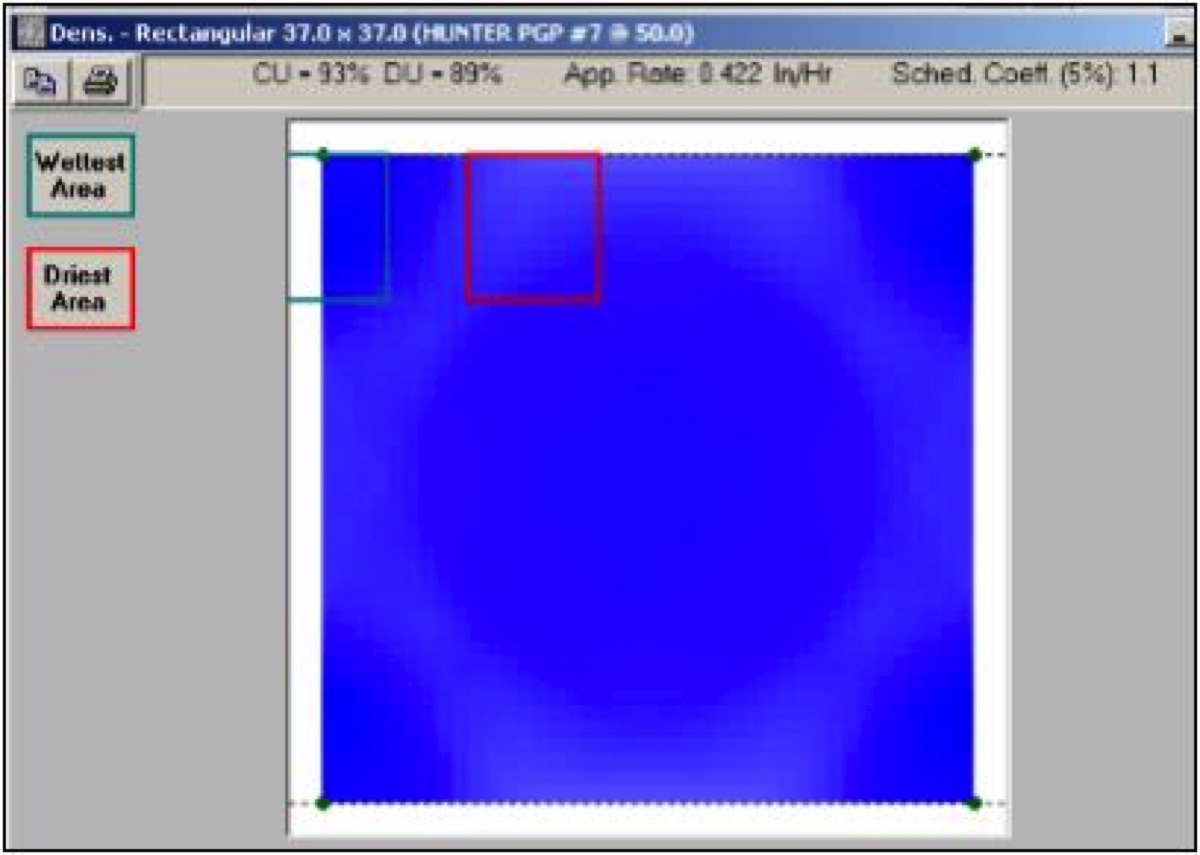

If you look at this head, there is a very slight doughnut right here on this densogram. Once again, remember it's in a labratory.

The CU on this system shows up at a 93%. In theory, that would be a phenomenal system. Your DU right here is at 89%. Pretty good CU, pretty good DU in the laboratory situation. But there is a very slight area here of a doughnut.

What that's telling us is that in the wintertime, this system works just fine. As soon as our ET goes up, we're going to start seeing those doughnuts of cure on that site. There is a spacing problem that we need to get out there and correct. And once we correct that spacing problem, those doughnuts go away.

That's called a stretched system. They're out there everywhere and you it said earlier. Why there's a stretched system out there is because our construction crew knows you know what, if I value engineer this and I take out three valves, I'll win that job. I can add one more head here, and one more head there, and one more head here because I know that.

Well yeah, it's overlapped. It's stretched. That doesn't mean it's right.

3 Layout & Uniformity Myths

Myth #1: Coverage doesn't always mean uniformity.

In fact, it usually doesn't. Uniformity has to do with what's in that book. But you gotta remember uniformity in that book is in a laboratory.

Myth #2: Triangle patterns are better than square patterns.

So triangle patterns are not always better than square patterns. The old rule of thumb was I set that up on a triangle spacing. Triangle spacing has way better CU than square spacing.

Not always true. It has to do with the site. It has to do with the turf plot we're watering. It has to do with all those factors that we gotta bring into it.

Myth #3: Head to head coverage is ideal.

A good rule of thumb that I've always used: If you got a system set up on 15' spacing based on catalog numbers, 15' nozzles, space the head about 12'.

Give yourself a little overlap because not one of those spacings that they have listed on those nozzles is out there in the field. Every one of them is in that laboratory under ideal conditions. You've got to set up a little different than what's in there.

The Irrigation Auditors Society through IA, they say give yourself a foot overlap. That's still a little close.

If you're not having to go to the controller and up your run times dramatically and you've got a little bit of an extra overlap on head to head, your systems are going to be more efficient because now we're not stretching them and we got the opportunity to to keep those systems tight. Keep everything rolling together because out there in the environment it's totally different than a laboratory. And you guys know that because you've been out there.